Pectin? What is the problem?

Pectin is a polysaccharide widely used as a thickener and stabilizing additive in modern industry: medical, confectionery, bakery, dairy, meat and many others.

Despite the fact that pectin is completely natural and is found in almost all plants, due to its high cost, there is a huge shortage of more than 65%.

Currently, acid-base or enzymatic methods for obtaining pectin are used in the world, the outdated technology of which is more than 200 years old, causing great harm to the environment.

For this reason, in most countries, factories either cannot be opened at all or are forced to spend huge amounts of money on cleaning up production emissions. In most of the countries of Europe, as well as the world, pectin is not produced.

The ever-increasing global tension in providing the population with food, as well as the market trend towards replacing chemical preservatives and thickeners with natural ones, makes us look for new solutions.

Solution.

Our innovative technology for the production of pectin is based on the extraction of the substance using ultrasonic cavitation in gentle temperature conditions without the use of strong acids, alcohols or other aggressive media.

Highly purified pectin obtained on our equipment fully complies with all international standards and meets the increased requirements for product quality.

The extraction of pectin according to the proposed technology is possible from any pectin-containing raw material with a yield of more than 90%.

Marketing.

Pectin production is a fast-growing business with an annual production increase of 3-4%, its global volume is more than 80 thousand tons per year.

The world’s largest manufacturers are: CP Kelco (USA), Danisco (DuPont) (USA), Cargill (USA), Herbstreith & Fox KG (Germany), Yantai Andre Pectin (China).

In recent years, new players have appeared on the market of pectin producers: Silvateam (Italy), Naturex (Switzerland), Ceamsa (Spain), Dangshan Haisheng Pectin (China).

Pectin products are mainly divided into three groups: High Methoxyl (HM) Pectin, Low Methoxyl (LMC) Pectin, Amidated low Methoxyl (LMA) Pectin.

Industry consumers: food industry, pharmaceutical industry, cosmetic industry.

The price of a citrus product for the food industry on the world market is 15-25 dollars per 1 kilogram, and for medical purposes – 30-80 dollars per kilogram. The price of highly purified pectin exceeds $ 100 per kilogram.

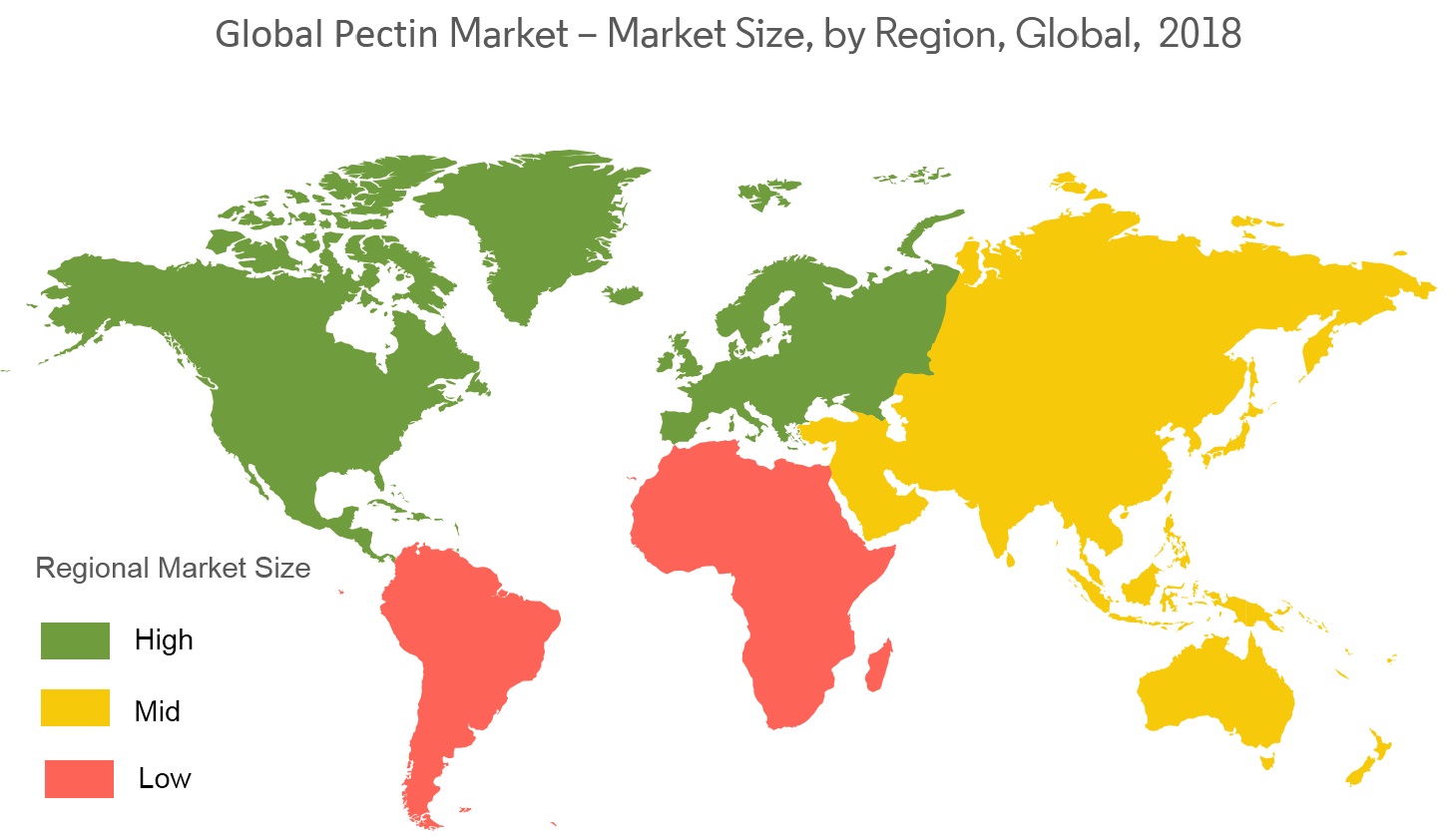

Global Pectin Market

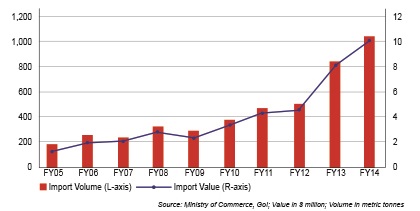

India has increased pectin imports fivefold in the last 10 years.

According to the latest study, the global pectin market is set to grow to US $1.87 billion by 2026, averaging nearly 8% over the forecast period.

The increased usage of pectin in fruit juices for improved mouthfeel, in acidified dairy applications for protein stabilization, low-calorie jams, and acidified protein drinks, has been supporting the growth of the market for the last few years.

The increasing awareness about the multifunctionality of pectin among food and beverage manufacturers, such as it reduces cooking time, improves texture and color, and increases the shelf life, are among the factors that have been fueling the market of pectin.

Fundamental differences from existing technologies.

The proposed pectin production technology is based on the extraction of pectin substances using the effect of ultrasonic cavitation and rotary cavitation extractors at gentle temperatures, without the use of strong acids and alcohols.

Any treatment of raw materials with aggressive media, both in gaseous and liquid form, is excluded. Waste and emissions, both in toxic and neutral forms, are completely excluded.

The pectin obtained using the proposed technology fully complies with the requirements of international standards and meets all the requirements for product quality.

Consider the main advantages of the proposed technology:

Research

On the development of the line for the production of pectin, ultrasonic technology, our company specialists have spent 7 years.

Breakthrough

More than 10 know-how are used in the design of the pectin production line.

Tests

The equipment has been tested in the most difficult conditions and has shown an exceptional margin of safety and wear resistance.

ECOLOGICAL

RAW MATERIALS

TECHNOLOGY NOVELTY

EFFICIENCY

“To raise new questions, new possibilities, to regard old problems from a new angle, requires creative imagination and marks real advance in science.”

Perspective production directions

The equipment showed high efficiency in the extraction of various substances. Cavitation extraction is the preferred method for isolating biologically active compounds from plant materials. The treatment of the aqueous solution and the subsequent cavitation effect ensure maximum extract yield in a very short time. Our equipment allows you to extract up to 98% of the substance.

Anthocyanins

Cannabidiol